Services - Expertise

Transform Electronics into a Long Runner.

We help you to operate existing systems in the long term and at the same time equip them with the functionality of tomorrow. Our goal is to sustainably minimise your repair costs and to offer your production plant a „second life“. We offer the following services:

Reliable availability of spare parts is indispensable to operate industrial plants efficiently. We have a large number of new, used and regenerated electronic components from various manufacturers in our shop.

Electronic components & devices:

Optoelectronics / Connectors / Sensors / Terminals / and much more

Pneumatic components & devices:

Valves / Cylinders / Repair kits

Used equipment:

for automation and electromechanics

Service:

1 year warranty on goods inspected by us / Payment by invoice for existing customers / Secure online shopping

We are happy to come to you for system analyses, maintenance work, repairs, spare parts installation and modernisations.

MakroElectronics GmbH offers a professional, technical on-site service, where the service time can be kept to a minimum and costly transport of your plant can be avoided.

/ Through an initial and detailed plant analysis, we identify potential problems in the electronics or mechanics. From this we can develop customised solutions to increase the efficiency and durability of your system.

/ Through regular maintenance work, we can keep your systems in operation in the long term.

/ In case of malfunctions, our experienced technicians are available for quick on-site repairs and installation of spare parts.

/ In addition, we offer plant upgrades as part of our on-site services to bring your technology up to date.

Contact us so that we can "get the most out" of your system with our reliable on-site service!

Stay technologically up to date. We help you to understand your equipment and system, as well as to train your repair skills. We look forward to hearing from you.

In order to avoid errors, problems and plant downtimes, you should know as much as possible about the condition of your plant. Our plant analysis helps you to minimise plant downtimes and the associated downtime costs.

Procedure of a plant analysis:

1) The data analysis is carried out by our competent personnel in cooperation with your technical staff. All technical data of the relevant assemblies such as manufacturer, type, series, software version, design, etc. are recorded. Optionally, we save your system data such as parameters of drive controllers or software statuses.

2) All recorded data is evaluated by us and bundled in an analysis report. The report contains all information on the recorded components, including information on product life cycle, availability, price development and delivery times.

3) In the evaluation analysis, we discuss the results of the plant analysis together. The evaluation includes an individual solution plan for the procurement and storage of hard-to-find or critical components. In the evaluation analysis, you will receive suggestions for spare parts stocking and spare parts management.

Robust industrial electronics are more in demand than ever before. MakroElectronics is your specialist in the procurement and brokerage of new and used equipment and spare parts. We take over defective goods and make them work.

Our equipment and systems trade industry includes,

among others, HMI operator panels, touch panels, industrial computers, PLC modules, control and drive technology. We find and organise discontinued/ obsolete components for you, e.g. electro-

lytic capacitors, IGBT, discrete semiconductors, transistors and thus significantly extend the

service cycle of your system.

Which device do you need?

Do you want to reduce maintenance and repair costs and secure the productivity of your system in the long term?

MakroElectronics offers many years of know-how in the field of RetroFIT and a competent, economically independent team. With our automation and control system solutions, your plant is once again state of the art. It works more efficiently, requires less maintenance and offers maximum availability, thus ensuring your long-term production reliability.

Do you want to continue operating existing plants and at the same time be up to date?

Software is a key component and essentially responsible for the productivity of a plant. Based on a functional analysis, we offer you the opportunity to individually incorporate your requirements. Thanks to our modular and constantly further developed software modules, we can thus realise powerful functions and visualisations tailored to your requirements.

Allow your production plant a "second life", independent of the former product supplier and with our modularised RetroFIT concepts.

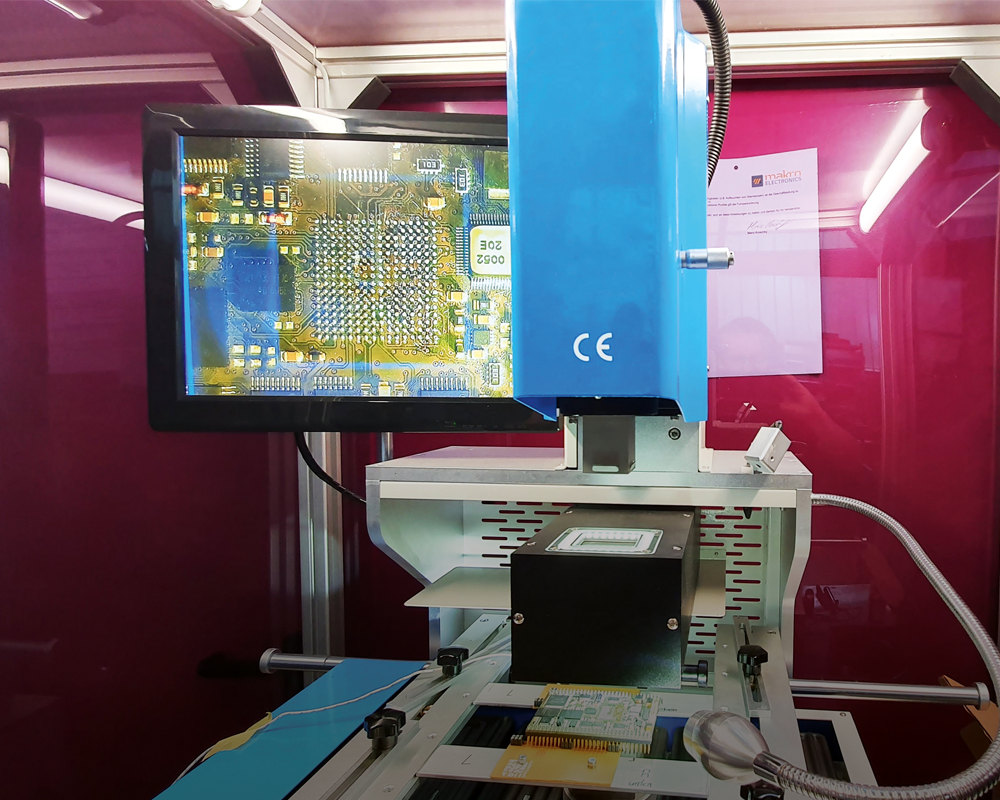

Every year, our qualified team of technicians repairs about 10,000 items. We offer repair of complete assemblies, individual printed circuit boards in professional quality and ensure that your equipment and industrial plant can remain in long-term and sustainable use.

Our repairs extend down to the component level,

i.e. we only repair what is really defective. This way,

we reduce costs for our customers and guarantee short delivery times.

/ Repair of displays, touch displays, motor controllers, PLC controls, IPCs, housings

/ Manufacturer-independent repair of electronic

components, e.g. from Beckhof, B&R, dmc Atlas, Lenze, Mitsubishi Electric, Rexroth Indramat,

Schaltag, Siemens